Vol. XVIII, No. 10, December 2018

- Editor's corner

- Is virtual reality the next BIG THING?

- Ocean5 wins Best New Center - Lounge/Restaurant design award

- Google is updating Maps as a B2C app

- Recent articles and in the press

- Construction cost increases challenging feasibility

- Most loved non-alcoholic drinks & their fastest growing flavors

- Home-basing - the new competition

- Miniature golf design for tomorrow

- A new generation of moms in on the way

- Willingness to spend time and money in a restaurant based on the noise level

- Update on the Tchotchke Index - what does it really tell us?

- eSports growing in popularity and coming to Walmart

- Trends reshaping dining out

Construction cost increases challenging feasibility

Many new community leisure venues (CLVs), including family entertainment centers (FECs), are developed based on financial feasibility studies that use existing centers as comparable projects. However, although the existing centers may be financially successful, replicating the center might not make a new center financially viable. Why? Because the existing center was built a number of years ago at yesterday's cost whereas the new center will be built at today's, or even tomorrow's cost, considering the time it takes to get a new center financed and open.

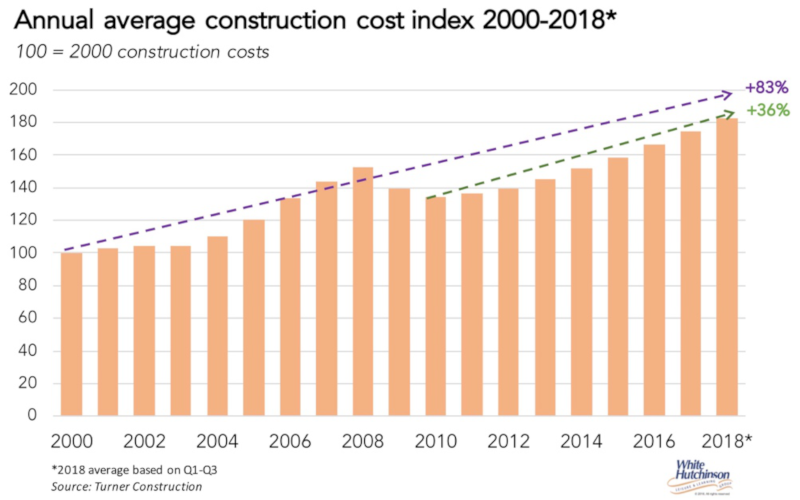

Construction costs are seeing significant increases. Several companies track non-residential construction cost inflation including RSMeans and Turner Construction Company. Using data from Turner (that corresponds with the results from RSMeans) shows that in the 3rd quarter of 2018, construction costs were 83% higher than in 2000 and 36% higher than 2010, the low point during the Great Recession. From as recently as 2014, construction costs are now one-fifth higher (+21%).

The reason construction cost increases are accelerating is due to a strong economy that is driving commercial construction that in turn is driving up material prices and resulting in a construction labor shortages. Rebuilding after the hurricanes and forest fires during the past few years has contributed to the construction demand and a shortage of labor and even materials.

We checked with our kitchen designer on kitchen equipment price increases. The answer was almost exactly the same increase as non-residential construction. The same if mostly true for almost all the fixtures, furniture and equipment that goes into a CLV.

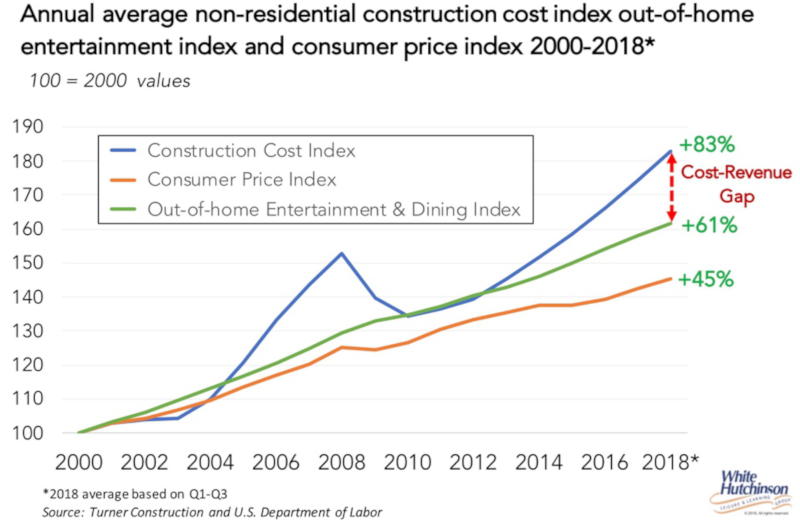

Since 2000, the prices for out-of-home (OOH) entertainment and dining have increased at a greater rate than overall inflation, but at a slower rate than construction costs, 61% compared to 83% for construction. There is now a significant cost-revenue gap.

The difference in the price increase rates for construction compared to OOH entertainment and dining has a deleterious impact on feasibility from the standpoint of generating the needed return on cost.

We'll use an example for a project built in 2012 compared to one developed in 2018 to illustrate the impact of the cost-revenue gap. Since 2012, commercial construction costs have increased an average of 4.6% annually for a total increase of 31%. The annual rate for construction cost increases since 2012 is almost triple the rate of over-all inflation (averaging 1.6% annually since 2012 for a total increase of 9%) and twice the rate that prices for OOH entertainment and food and beverage have increased since 2012 (averaging 2.3% annually for a total increase of 15%).

We'll assume the 2012 project cost $5.0 million, had revenues of $4.0 million and an EBIDTA of 25%. Here's a comparison of the return on investment in 2012 versus the same project being developed today using the respective price increases.

The equivalent facility to the 2012 CLV now cost $1,550,000 more. The return on investment is now lower than in 2012. In this particular illustration the difference might not seem that great, but it could well be the difference between the ability to obtain the needed financing versus the project not being financeable, especially at today's higher interest rates.

Today's challenge

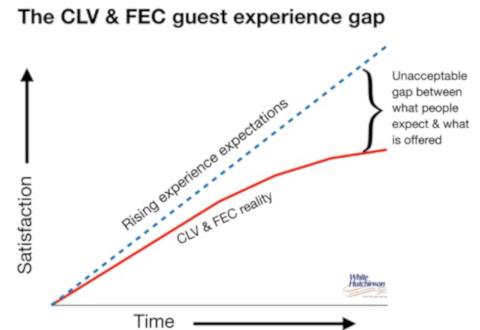

Today, much more so than in the past, to be successful, CLVs need to attract the higher socioeconomic guests who account for nearly three-quarters of all revenues - 70% by the top 40% income households and 71% by bachelor's + college degree households. That segment of target guests have high expectations for the quality, ambiance and design of businesses they will visit as well as their operations. Their standards are often unforgiving. Underinvestment in the ambiance and finishes, all of which affect the quality of the guest experience, results in a guest experience gap and poor performance. This is exactly what happens when a project's design doesn't meet their expectations.

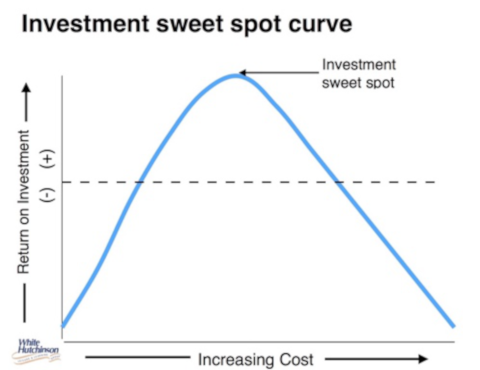

There is an investment sweet spot that has to be hit in order to maximize revenues with higher socioeconomic guests. With today's high and increasing construction costs, it is critical to assure that the needed quality will be maintained to attract guests. Cheapening the quality and the finishes is no longer a viable option, as it will only result in lower profitability. In fact, when targeting the higher socioeconomic consumer, underspending on quality can result in a lower return on investment than overspending.

An accurate cost estimate

Estimating an accurate cost for a project is extremely important during the financial feasibility phase. Using costs from other projects (yesterday's costs) or trying to use per square foot estimates typically result in costs being underestimated, resulting in inadequate funding to complete the CLV as planned. Once a project is funded, it becomes very difficult to either raise additional funding or reduce the completion costs. What normally happens in that situation is that the only things that can be reduced in cost are the ones most important to the guests, the finishes or eliminating an attraction. So as a result, the CLV never achieves its projected revenues and profitability as it lacks the required quality and/or features to attract the target market.

The need for preliminary plans

To assure that the projects our company produce for our clients have the required level of finishes needed and don't have budget overruns, our company does two important things. During financial feasibility, we develop preliminary plans and work with an experienced commercial contractor to estimate construction costs. Then during the design phase, we involve the contractor and its sub-contractors to continually value engineer the design as the construction plans and specifications are developed.

The need for upfront value engineering

Value engineering is the process of designing unnecessary costs out of a project. The problem is, the process typically occurs after the project is designed and construction bids exceed the budget. Then, it's too late to attack the costs of major building components and systems, where the greatest savings may be possible, without major delays and additional design costs. About the only way to cut the costs at the phase is to cheapen the interior and finishes. So instead of acoustic ceilings, the structure is exposed and noisy. Instead of carpet, it's concrete floors, and instead of comfortable seating, budget furniture. The value of the guest experience is engineered out. The result? A planned Macy's building that ends up being a Walmart, so you don't get the Macy's customers that the business plan projected.

Instead, value engineering needs to occur during the design phase when design decisions have the most flexibility and the maximum benefit, not during the bid stage. And the objective shouldn't just be to lower cost, but to achieve the desired guest experience most economically. To do this, our design team also includes the local contractor and subcontractors who know how to find the most economical construction systems and materials to use without diminishing the guests' experience. We monitor the entire process as we understand what the targeted guests want and expect and what must be maintained to deliver the required experience to achieve the required financial results.

With today's higher construction costs, development of financially successful CLVs is much more challenging than in the past. It is critical during the earliest stage of the project accurately estimate costs and then to continually value engineer and monitor costs during the design phase.

Vol. XVIII, No. 10, December 2018

- Editor's corner

- Is virtual reality the next BIG THING?

- Ocean5 wins Best New Center - Lounge/Restaurant design award

- Google is updating Maps as a B2C app

- Recent articles and in the press

- Construction cost increases challenging feasibility

- Most loved non-alcoholic drinks & their fastest growing flavors

- Home-basing - the new competition

- Miniature golf design for tomorrow

- A new generation of moms in on the way

- Willingness to spend time and money in a restaurant based on the noise level

- Update on the Tchotchke Index - what does it really tell us?

- eSports growing in popularity and coming to Walmart

- Trends reshaping dining out